I have been hoping that I wouldn't have to write this post but reality bites sometimes and here I am, on the eve of launching our first range of cycling gear, writing about why we have decided to delay the manufacture of our cycling bib shorts but go ahead and start selling our cycling jerseys for men.

I know, you've all been waiting for us to launch our first range of cycling gear. We have teased you all throughout the prototype stages with sneak peeks on social media and we know, it has been a long period of testing. The reason for this elongated slab of testing time has come down to one thing... the bib shorts. The short sleeve jerseys were spot on from the first prototype. Hands down best jersey we and our testers have ever worn. But the bib shorts have been another story. Comfort and cut is spot on. The chamois (pad) is really good, I've been using them for years and they last. But the problem with the Vegan Athletic bib shorts has been a problem that both myself and Greg have had for a long time. We hate sublimated (printed) panels on bib shorts.

Now not many of you are going to understand what we mean when we say sublimated so I'm going to show you and teach you because it's something worth knowing about so you can make better informed decisions in the future when it comes to purchasing cycling bib shorts.

In the photo above is a sample pair of Vegan Athletic bib shorts where the side panel and band have been sublimation printed. This means that those two sections of the shorts are made from a white lycra fabric that is printed on. The panel that runs on the inside of the crouch and around the backside is made from a pre-dyed lycra, which you can't print on, it's just 100% black, or blue or red or what ever pre-dyed colour you choose. This creates a two toned look. No matter how well you colour match the printed panel to the pre-dyed panel, you will always get a two tone between the two types of fabric. This, in our opinion doesn't look good and it certainly doesn't age well. Sublimated panels will fade lighter over use and time and if you brush up against a rough surface you will certainly see some horrible white threads become exposed through the top printed surface.

Pre-dyed lycra is the best stuff to make cycling shorts out of but if you want to print a logo on it you have to use either a heat transfer or rubberised screen printing method. These methods look brilliant when you transfer them. They look brilliant for the first few weeks, or months if done properly, some can even last a good year if you look after them. But ultimately, these printing methods on pre-dyed fabric eventually crack or peel off. That is why so many cycling brands just choose the safest option and sublimate the panels they want to have logos or colours/designs on. Nothing can peel off or crack, it's always the cheapest option and 9/10 people won't really care or even know the difference. And that is where we have decided to put our foot down. We want our gear to last. We want you to feel confident that when you buy our bib shorts, you know you are going to get a long lasting product.

In the photo above (thanks to Kirsty Baxter) I'm wearing a prototype pair of fully pre-dyed lycra Vegan Athletic bib shorts. They use a heat transfer method to print the letters onto the side panels. I'll confidently say that these have been the best pair of bib shorts I've ever owned. But, the heat transfers were starting to peel up after I put them through some hard stretch testing and washing. Since then we have looked high and low at finding a print method that sticks and stays onto pre-dyed lycra, that never peels and never cracks. A good friend told me that you shouldn't try and find perfection in manufacturing but we have spent hours and hours and hours testing and deciding how we can make a pair of bib shorts that in our eyes are as close to perfect as possible.

So here is the deal. We gave sublimated one final test this week with some more prototypes that we were highly specified with fabric choice, stitching patterns and colour matching. We thought we possibly may be able to start selling these with the new jerseys that have been ready to go since the start of the year. But, as it has been since the beginning, this final round of sublimated bib shorts just weren't up to the high standard that we hold so close to our quads. Mind you, they are really good shorts but we just don't want to put them to production. We just wan't to give you the best and the good news is that we know what that involves and have made the decision to go ahead on that.

We have got one more round of prototypes to make for what we believe is the answer to all of the problems we have pointed out above. We will need a few more weeks to get these shorts right and when we do, you better look out because we are going to hit you up hard a fast to make these bib shorts the only bib shorts you will ever want to buy.

The question was raised this week when we got the last set of sublimated sample bib shorts. It was me actually who raised the question to Greg. I said "Greg... Do you think we can sell the jerseys without the bib shorts? I really don't want to just sell the jerseys, it's crazy doing that..." And Greg looked at me, through his phone on FaceTime and said "Listen here little Prawnie, we are going to sell these jerseys without the bib shorts, we are going to tell everyone why and we are going to look after our people for hanging out so long with us. I know how good these shorts are and you are going to make sure people get the best and that is that."

So here I am, I've explained the truth about bib shorts to you all and I'm just happy that I can see the light at the end of this particular product tunnel. I am terribly sorry that it has delayed us, that it has stopped us from being able to sell a full kit in one go but I'm not sorry that we at Vegan Athletic are continually trying to toe the line with the best quality we can possibly create.

Yours truly,

DB

Más historias

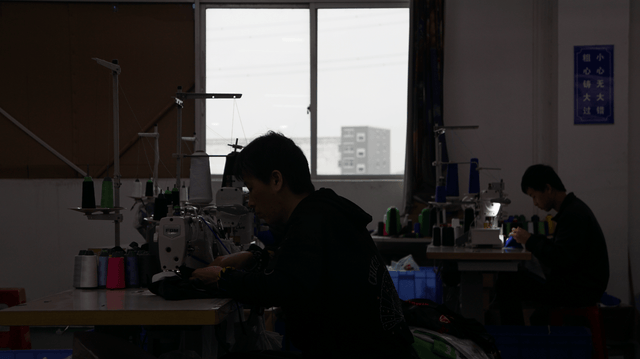

Vegan Athletic Factory Visit